Compressive Strength Test Machine

Compressive Strength Test Machine

Model TG-300B automatic constant stress cement pressure tester is designed to test the compressive strength of cement mortar, capable of completing the test automatically in accordance with the requirements of GB/T17671-2005 The Strength Testing Method for Cement Mortar and GB/T10238-2005 Oil Well Cement and GB/T19139-2003 Oil Well Cement Testing Method. With its uniform loading and load retention control, the equipment allows LC display, saving, printing and data base management of test data and curves, applicable to various research work of scientific research institutes and educational institutions. The tester is composed of the frame, the hydraulic system, the integrated electric control system and control-dedicated PC, characterized by its compact structure, aesthetic appearance, simplified operation and reliable safety.

Product Description

Main Performance Indexes and Technical Data of the Equipment

The TG-300B automatic constant stress cement pressure tester is designed to test the compressive strength of cement mortar, capable of completing the test automatically in accordance with the requirements of GB/T17671-2005 The Strength Testing Method for Cement Mortar and GB/T10238-2005 Oil Well Cement and GB/T19139-2003 Oil Well Cement Testing Method. With its uniform loading and load retention control, the equipment allows LC display, saving, printing and data base management of test data and curves, applicable to various research work of scientific research institutes and educational institutions. The tester is composed of the frame, the hydraulic system, the integrated electric control system and control-dedicated PC, characterized by its compact structure, aesthetic appearance, simplified operation and reliable safety.

The Framework: comprising of a seat, a cross beam, a support and two columns as an integrated part, provided with a safety shield to ensure the safety of test operators during the test. The oil cylinder, which is fixed to the seat, has a piston stroke of 45MM. The plunger is covered with a dust hood to prevent dust from entering the oil cylinder while the piston rises. A combined seal is adopted for the oil cylinder and piston. An oil overflow hole which is specially designed on the inner wall of the oil cylinder allows the friction coefficient between the working oil cylinder and the piston to reduce to the minimum and plays a protective role, thus ensuring the precision and safety of the tester.

The Hydraulic System

The whole hydraulic system includes an oil tank, a hydraulic-dedicated oil pump motor set, check valves, proportional overflow valves, overflow valves, solenoid valves and a high-precision oil filter, etc.

The Control System

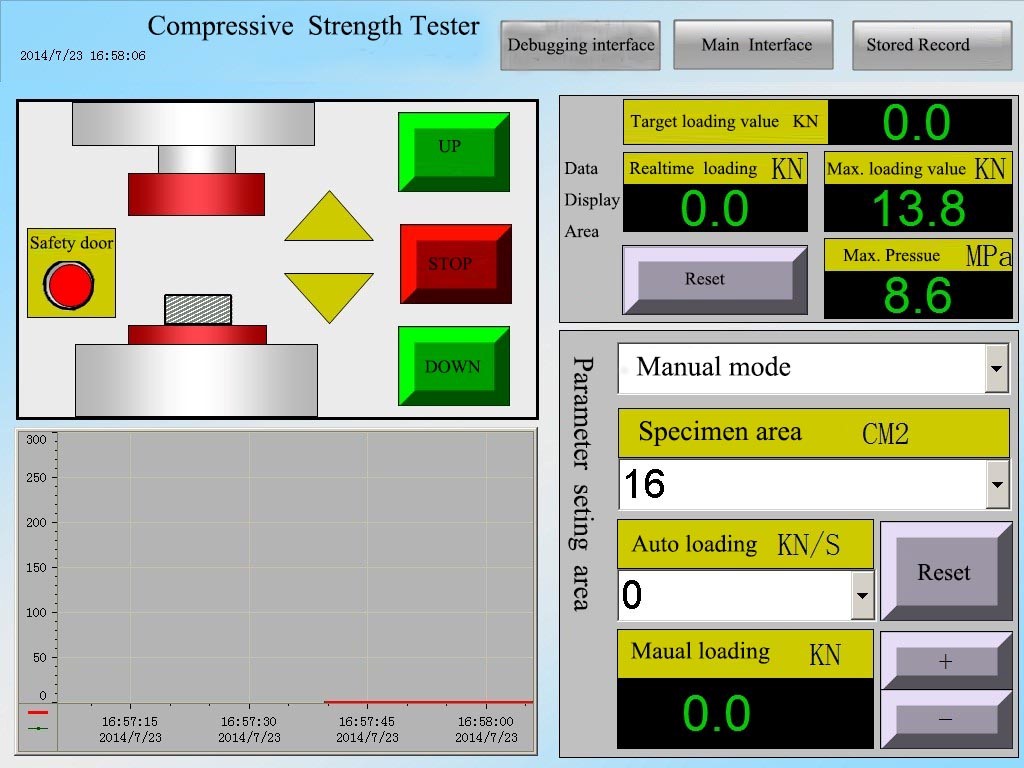

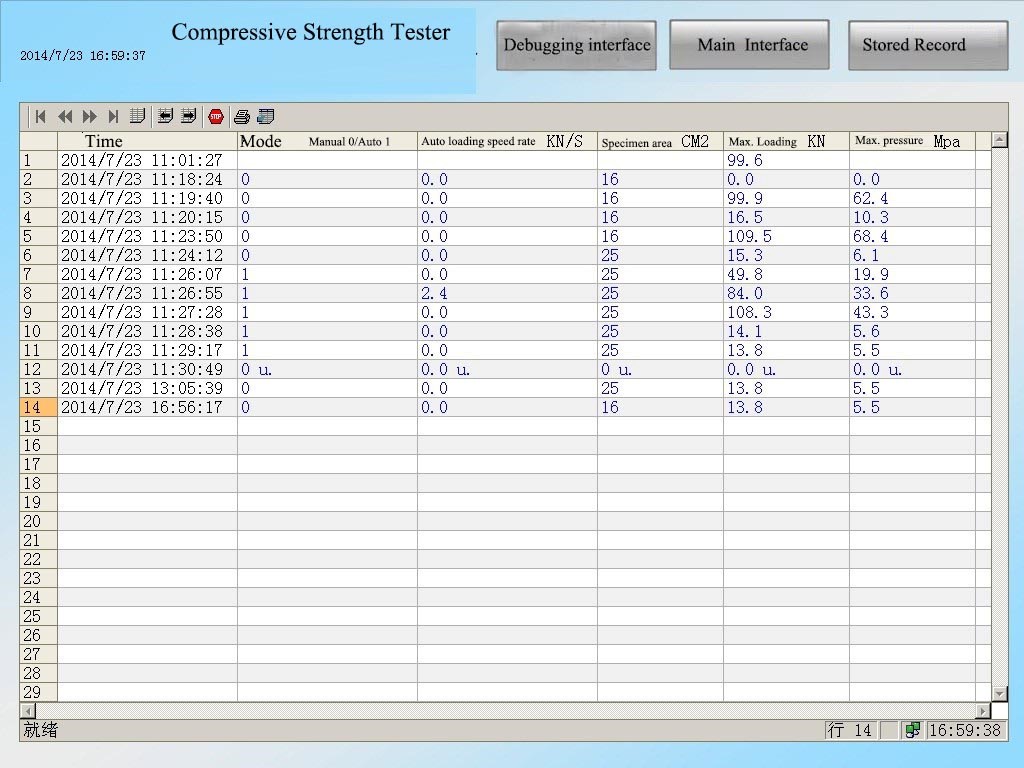

Operating Interface

There are two loading modes: manual and automatic.

The adoption of an integrated industrial touch screen control and PLC system, which represent the top level of the control system development, allows the closed loop control of test force, the control of uniform test force, and the screen display of test force, peak values and test curves, and enable the equipment to process data in accordance with the requirements of GB/T17671-2005. A full touch operation and control mode is intelligently set by the expert system; the multi-channel saving of parameter documents is used for a simulated representation of test process and reanalysis of test data. The adoption of a total digital program-controlled amplifier allows automatic reset and shift operations with the aid of a computer. The software system gives full play to the powerful function of computer as a virtual instrument. The multiple test curve display function and the overall process test data saving function ensure the reprocessing of test data.

Specifications

|

Designation |

Model No. |

Max. test force |

Measurable range of test force |

Precision of test force indication |

|

Cement pressure tester |

TG-300B |

300kN |

18kN-300kN |

±1% |

Main performance indexes

Max. test force: 300kN;

Measurable range of test force: 18kN-300kN;

Precision of test force indication: ±1%;

Piston diameter: Φ125 mm;

Piston stroke: 0 - 45mm;

Max.travel speed of piston without load:35mm/min

Compression space: 0 - 80mm

Overall outline size: 697mm×775mm×1450mm